PRODUCTS

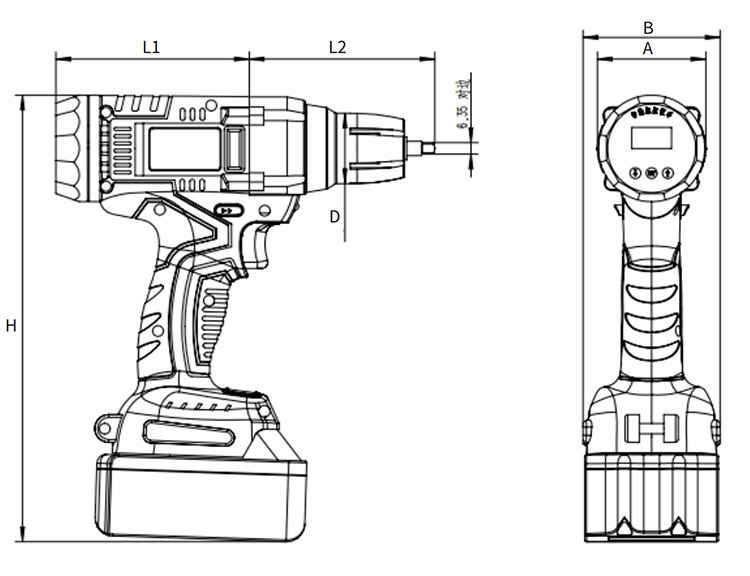

Pistol cordless pulse tool

Category:

E-mail:

Introduction

-

Pistol electronic pulse tool main functions

● Electronic Pulse Drive, No Reactive Force

The SMG-LDY electronic pulse torque wrench utilizes advanced electronic pulse drive technology, with no reactive force. It operates with minimal vibration, significantly improving work efficiency and operator comfort. It is ideal for long-duration continuous operation.● Lightweight Design, Ideal for Mobile Operations

Compared to conventional pneumatic or electric torque wrenches, this product has a compact body structure and weighs as little as 2.1kg. It is easy to carry and is ideal for use in manufacturing workshops and assembly lines. It takes up minimal space and is very convenient.● Intelligent Automatic Shutoff Function, Reduces Operational Risks

Equipped with an automatic shutoff function, the system automatically stops the drive once the preset maximum torque value is reached or the fastening task is completed. This prevents over-torquing or damage to the bolts. This design is particularly suitable for handling precision components or long-term installation projects, reducing the risk of human error and equipment damage.● High Precision Control, Ensures Bolt Connection Quality

Utilizing advanced motor drive and closed-loop feedback systems, this tool provides a torque range from 5 to 150 N·m, with adjustments in increments of 1 N·m and high repeatability. It ensures the stability of bolt connections and long-term reliability, making it particularly suitable for industrial scenarios with high-quality requirements.● High Speed, Meets Various Fastening Requirements

The drive system supports up to 3000 cycles per minute (RPM), allowing for quick response and completion of fastening tasks. Whether it’s for mass production or individual precision bolts, it can complete the task with higher efficiency, greatly improving the overall productivity of the production line.

Oil pressure pulse structure:

● 1 million times no repair/maintenance

● No reaction force, small vibration

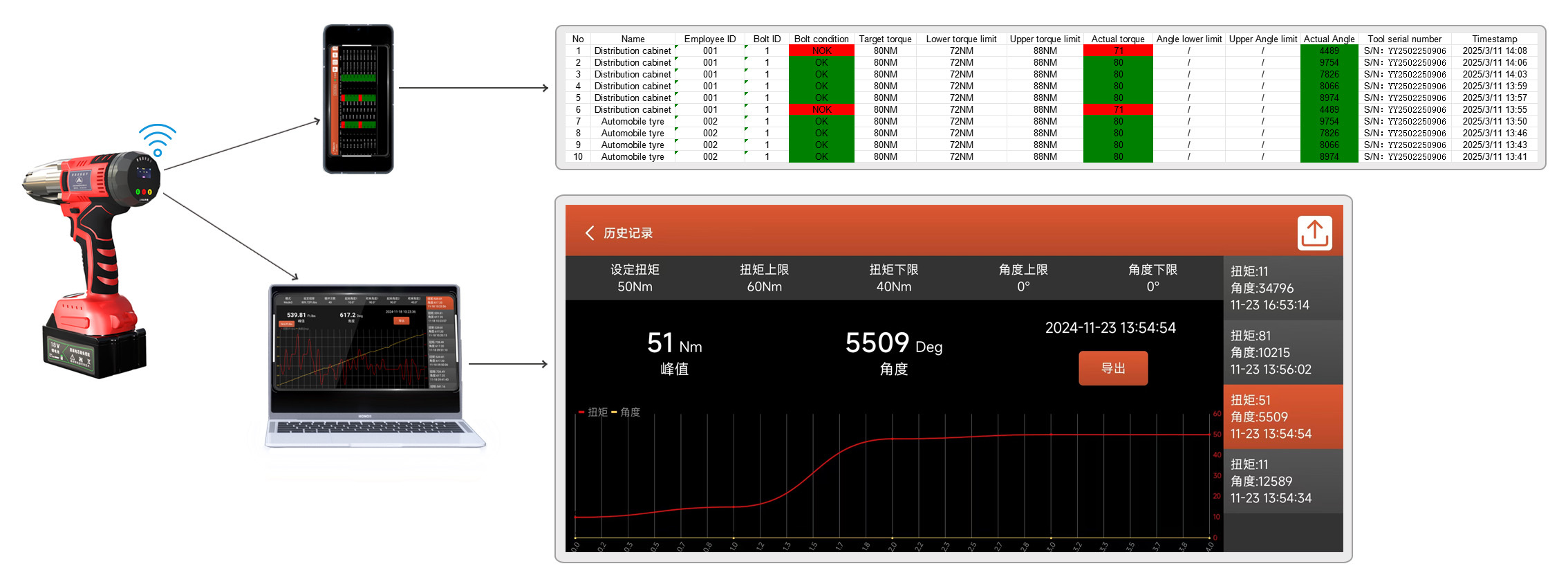

IoT communication:

● Support exporting data through WiFi and USB

● Connected to the upper computer and robot through the Internet of Things, and connected to the MES management system

Click to enlarge

Click to enlarge