PRODUCTS CENTER

A professional enterprise engaged in the research and production of twisting tools

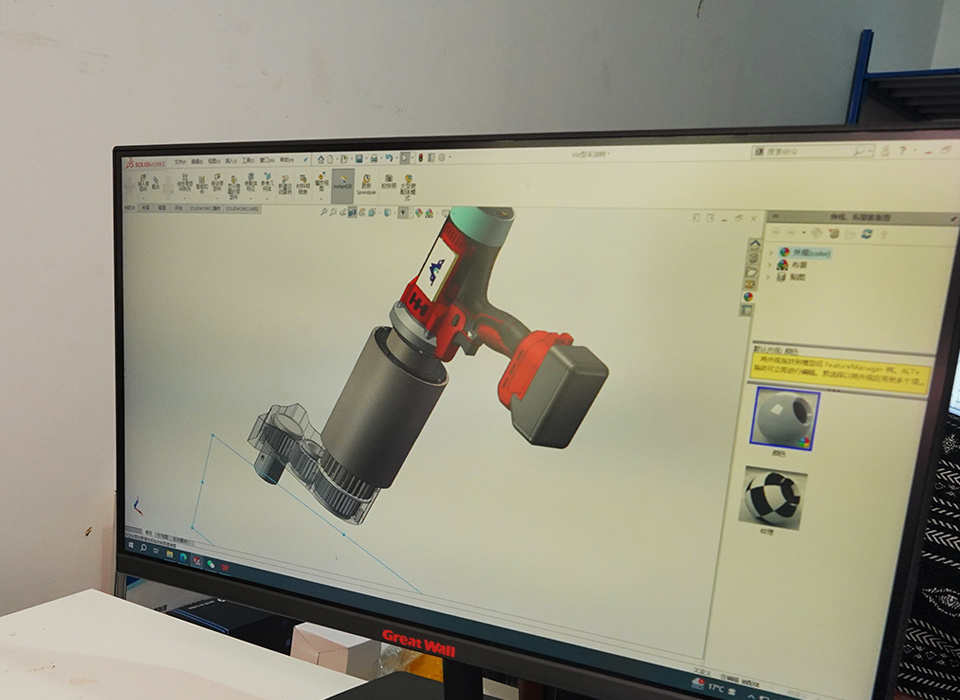

Professional cordless torque wrench with data transmission and digital display

The company was established in

Cases

More than 80 employees

Customers

A professional engaged in the research and production of tightening tools enterprises

Who We Are?

A manufacturer of tightening tools

What Can We Do?

Our products are mainly battery torque wrench, pneumatic torque wrench, electric torque wrench,Screw shaft,related tools/accessories.

Shanghai SMG Intelligent Technology Co., Ltd

Shanghai SMG Intelligent Technology Co., Ltd, located in Shanghai, is a manufacturer of tightening tools. Our products are mainly battery torque wrench, pneumatic torque wrench, electric torque wrench, Tighten the shaft and related tools/accessories.

We adopt world-class technology of tool manufacturing, and associate with planetary gears research institute and elite engineers to ensure high-quality products. Relying on German technology and continuous innovation of our senior engineers in tightening tools industry ...

FACTORY

A professional engaged in twisting tools research and production of enterprises

Office

Conference Room

Warehouse

Machining center

WHY CHOOSE US

A professional enterprise engaged in the research and production of twisting tools

Shanghai SMG Intelligent Technology is a trade, scientific research, manufacturing as one of the entity enterprises, long-term engaged in the research and development of bolt fastening technology products, manufacturing and sales, for many domestic and foreign bolt fastening projects to provide solutions and equipment.

Technical Cooperation and R&D Capabilities

We have introduced advanced German machinery design and manufacturing technology, using 3D modeling and finite element analysis to optimize our designs. We have also worked closely with authoritative gear research institutes to develop torque wrenches with independent intellectual property rights.

We have introduced advanced gear hobbing machines, rolling machines, and grinding machines from around the world to establish a processing center, ensuring that the tolerances of the parts are within micrometers, providing a solid equipment foundation for producing high-precision torque wrenches.

NEWS CENTER

A professional enterprise engaged in the research and production of twisting tools

Advantages of Using a Cordless Battery Torque Wrench for Valve Operation

2026-03-06

Beijing Petrochemical Exhibition

2024-10-24

What are the dangers of loose fasteners such as high-strength bolts?

2024-07-29

What should I pay attention to when tightening flange bolts with an electric wrench?

2024-07-29

OUR PARTNERS

we are committed to becoming a global leader in the field of bolt tightening.